You are here:

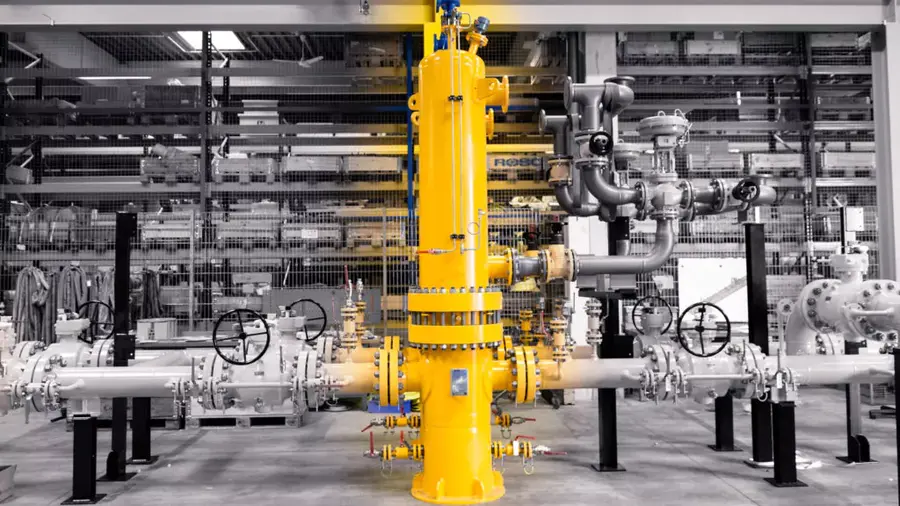

Shell and tube heat exchanger

As experts in the development and manufacture of heat exchangers, we offer customized solutions for a wide range of industrial applications. Our products are specially designed to efficiently heat or cool gases while meeting precise system requirements. Whether to compensate for the Joule-Thomson effect when reducing pressure, for safe temperature control in sensitive processes or for decentralized gas preheating - our robust welded steel constructions stand for reliability, efficiency and durability.

With various designs, such as tube bundle heat exchangers, electric preheaters or water bath heaters, we cover a wide range of applications and guarantee maximum safety and optimum performance in any operating environment.

With various designs, such as tube bundle heat exchangers, electric preheaters or water bath heaters, we cover a wide range of applications and guarantee maximum safety and optimum performance in any operating environment.

VEV tube bundle heat exchanger

The VEV/VEV-L heat exchangers heat gas to meet system requirements or to compensate for the Joule-Thomson effect in the event of pressure reduction. They can also be used as coolers and are designed as horizontal or vertical welded steel constructions.

VEV-LS Fuel Gas Performance Heater

Heat exchangers heat gas for system requirements or to compensate for the Joule-Thomson effect when pressure is reduced. They can also be used as coolers and are available in vertical or horizontal welded steel construction.

VEV-Ex electric preheater

Heat exchangers (heat exchangers) heat gas to meet system requirements or to compensate for the Joule-Thomson effect that occurs when pressure is reduced. They can also be used as coolers and are designed as vertical welded steel constructions.

VEV-DR safety heat exchanger

The VEV/VEV-L heat exchangers heat gas to meet system requirements or to compensate for the Joule-Thomson effect. For increased safety, double-tube heat exchangers (VEV-DR/VEV-L-DR) are often used, whose double-walled tubes with leakage monitoring ensure safe and uninterrupted operation. They are designed as horizontal or vertical welded steel constructions.

VH Water bath heater

Indirect waterbath heaters of type VH are heat exchangers that heat gas decentrally if no boiler system is available. They compensate for the Joule-Thomson effect in the event of pressure reduction or provide a defined gas temperature. They are typically used in gas field probes, pipeline GDRM and compressor stations, cavern storage facilities and power stations. The design is a horizontal welded steel construction.

Increased efficiency. Print stability. Transportability.

The use of heat exchangers (natural gas preheaters, natural gas heat exchangers) increases the efficiency of your systems. Preheating the gas makes your system pressure-stable and the gas therefore transportable.

Most gas systems require compensation for the so-called Joule-Thomson effect. With this effect, the gas temperature drops at a constant flow rate due to a reduction in pressure. As a result, the gas cools down - e.g. through the use of pressure reduction systems, fluctuations in outside temperature or the flow through long transport lines. If the gas is heated at selected system points, pressure stability or gas temperatures can be achieved that make a subsequent system component more efficient, e.g. gas turbines.

We offer shell and tube heat exchangers for heating gases, saturated steam or water in gas technology systems.

We calculate our heat exchangers optimally for your process. An optimally adapted design conserves resources and makes your overall system more economical.

Most gas systems require compensation for the so-called Joule-Thomson effect. With this effect, the gas temperature drops at a constant flow rate due to a reduction in pressure. As a result, the gas cools down - e.g. through the use of pressure reduction systems, fluctuations in outside temperature or the flow through long transport lines. If the gas is heated at selected system points, pressure stability or gas temperatures can be achieved that make a subsequent system component more efficient, e.g. gas turbines.

We offer shell and tube heat exchangers for heating gases, saturated steam or water in gas technology systems.

We calculate our heat exchangers optimally for your process. An optimally adapted design conserves resources and makes your overall system more economical.

Manufacturer of heat exchangers for gas preheating for high-pressure systems

- Efficient gas preheating: Optimizes gas transfer by heating it to the required temperature.

- Pressure stability: Minimizes pressure fluctuations in the system for safe operation.

- Transportability of the gas: Enables smooth and safe gas transportation.

- High-pressure capability: Specially developed for use in high-pressure gas supply systems.

- Energy efficiency: Reduces energy losses and increases the overall efficiency of the system.

- Durability: Robust design for long-term and reliable operation.

- Economical operation: Reduces operating costs through increased efficiency and reduced energy consumption.