Gas mixer, Typ VGM

Characteristics

- efficient mixing of gases

- for all gases according to G260

- for non-aggressive special gases

Options

- customer specific design

- for other codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.)

- customer specific approvals

- customer specific tests

- application for sour gas (NACE)

- design for low temperature down to -50 °C

- design pressure up to 300 bar

- design temperature up to 250 °C

General

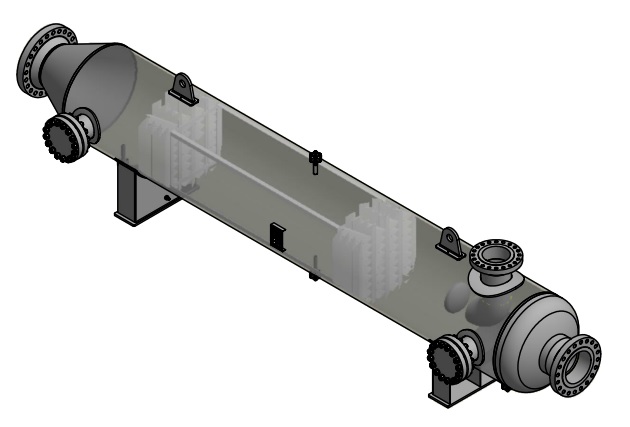

Gas mixers type VGM are used to mix two gaseous media with each other.

The design is a welded steel construction in horizontal design.

Calculation

The calculation of the diameter and length of the mixing chamber in relation to the type of packing used for the respective operating data ensure the careful mixing of the two gases.

Function

The main medium flows horizontally through the gas mixer. The second medium is supplied via a laterally arranged nozzle.

Vortexing internals produce coarse mixing of the gases. Fine mixing is achieved in a downstream mixing chamber. The mixing chamber is filled with packings whose special shape and random arrangement of the packing bring about good gas mixing. The packings are made of material 1.4301 and are thus of robust design for abrasion and corrosion. In case of condensate formation, the various sections of the gas mixer should be drained regularly.

Anschließend strömThe mixed gas then flows to the outlet nozzle of the gas mixer.

Quality management

- DIN EN ISO 9001 certified

- Our vessels are tested according to AD 2000 regulations and CE-certified according to EC / PED 2014/68 / EU. The examination is carried out by authorized inspectors (TÜV, Lloyd’s Register, etc.).

- Test and material certificates are prepared by the inspectors according to the design specification.