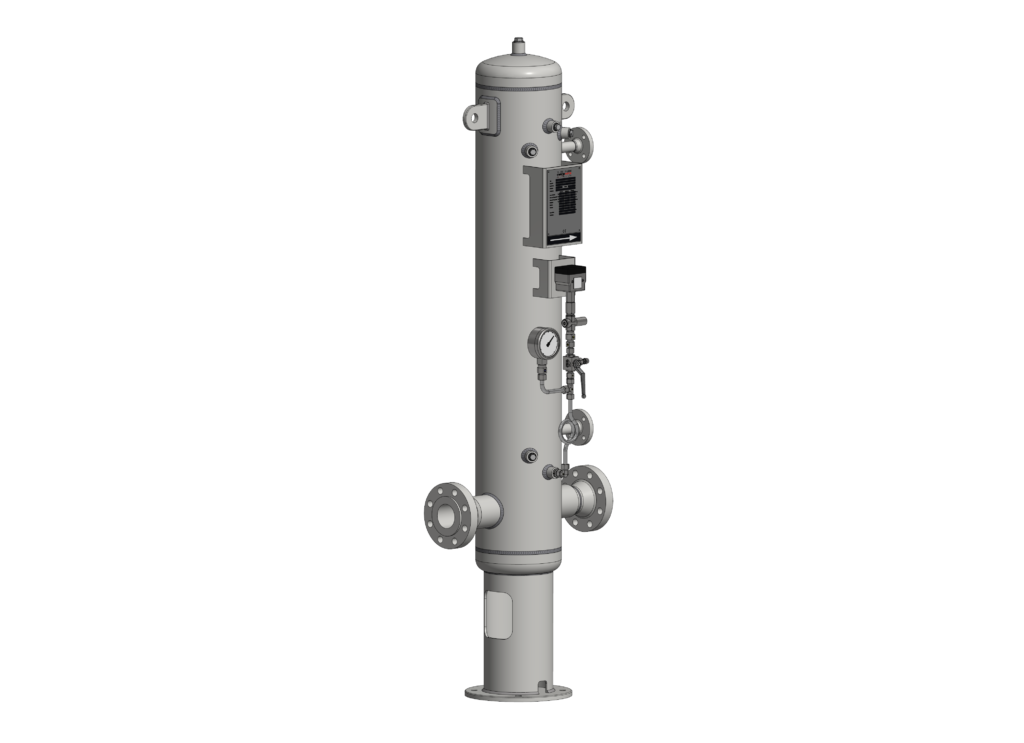

Safety first – The safety heat exchanger from GTS!

Safety heat exchangers have become an established and valued standard in the chemical, power, heavy and light industry, oil and gas, marine, transportation, refrigeration, food and beverage sectors. This can be heat exchange between a medium that is hostile to the environment and a medium that is released back into the environment, or heat exchange between two media that react with each other. This results in the typical areas of application for safety heat exchangers, such as in the oil cooling of turbines, gearboxes and compressors in service water heating, the wood industry and in the chemical and petrochemical industries, where mixing must be avoided at all costs for process reasons.

In times of stricter laws and regulations regarding safety requirements for environmental and water protection, the double-tube safety heat exchangers from GTS Thielmann Energietechnik are the technology of choice.

Reasons for installation of GTS safety double-tube heat exchanger with leakage detection

The decisive installation reasons usually result from the following requirements:

- Compliance with legal requirements that are becoming increasingly stringent

- Safe transport of environmentally hazardous media

- Safety motive for hazard reduction and liability limitation

- Reduction of insurance risks, protection against liability risks

- Environmental issues are becoming increasingly important

- Moral and ethical reservations regarding the occurrence of leaks in the heat transfer of hazardous chemicals or media

- Protection of people (personnel in buildings), the plant operator is responsible for the safety of the personnel

- Controllability of leaks/ leakage with simultaneous protection of the environment, early leakage detection for damage prevention by appropriate leakage monitoring systems

- Avoidance of operational interruptions – protection of sensitive and expensive production equipment. Production downtimes can be very expensive!

- Low pressure loss with maximum heat transfer